Case Studies

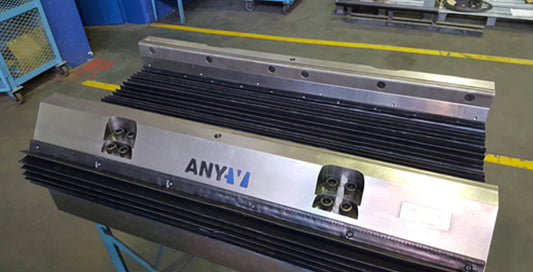

Testing the Any-V at Bell Equipment

Bell equipment had a workflow that consisted of two shifts of plate bending operations, followed by a third shift changing the tooling and setting up the machine for the next...

Testing the Any-V at Bell Equipment

Bell equipment had a workflow that consisted of two shifts of plate bending operations, followed by a third shift changing the tooling and setting up the machine for the next...

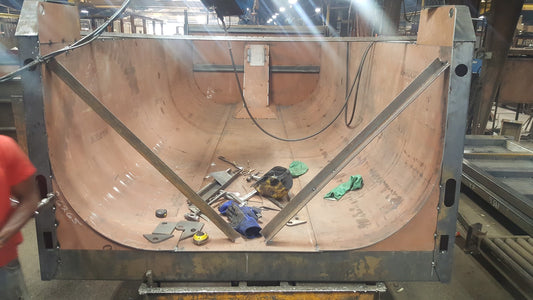

Case Study - Warren, Inc

The client makes load bodies in 6mm Hardox 450 and each side needed ten bends. Added to the high production cost with over four hours machine time, the accumulated errors...

Case Study - Warren, Inc

The client makes load bodies in 6mm Hardox 450 and each side needed ten bends. Added to the high production cost with over four hours machine time, the accumulated errors...

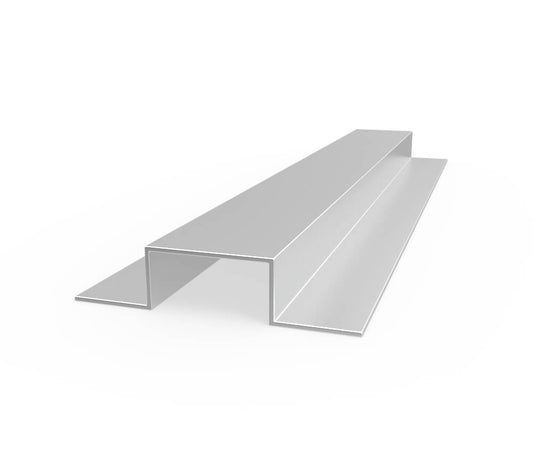

Case Study - ShelvCraft cc

Shelvcraft used U-shaped channels as reinforcing on their shelving products. The channels were being bent in 4 strokes, out of 1mm thick material, and this was identified as a bottleneck...

Case Study - ShelvCraft cc

Shelvcraft used U-shaped channels as reinforcing on their shelving products. The channels were being bent in 4 strokes, out of 1mm thick material, and this was identified as a bottleneck...