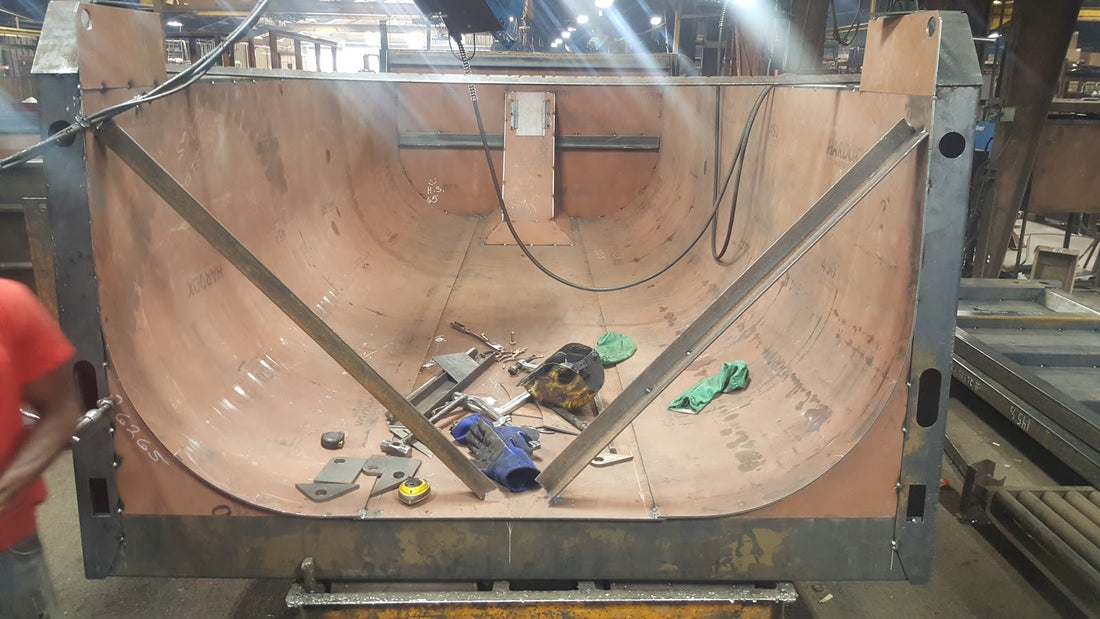

The client makes load bodies in 6mm Hardox 450 and each side needed ten bends. Added to the high production cost with over four hours machine time, the accumulated errors made assembly really difficult.

Using a roller tool die, and a radius punch to bend the large radius in three strokes instead of ten, the sides were faster to make — taking only 20 minutes — and, thanks to the increased accuracy, easier to assemble. The bend radius also comes out more consistent, letting the final product realise the design intent.